Increasing Strength and Reliability of Interference Fits

Por um escritor misterioso

Last updated 22 dezembro 2024

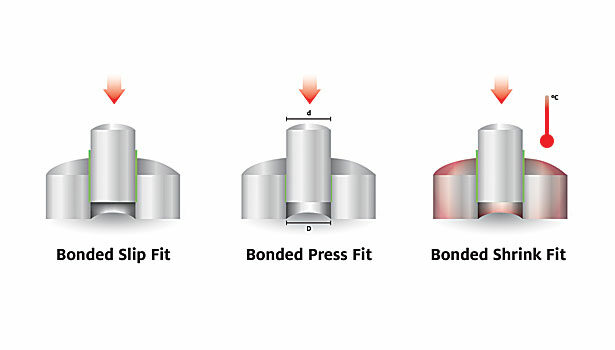

Interference fits, commonly referred to as press fits and shrink fits, are traditional methods for joining cylindrical parts. In an interference fit, the inner part—such as a shaft, bearing or bushing—is machined to be bigger than the mating hole of the outer part—such as a gear or housing. The larger part is then forced into the smaller part. Both parts deform slightly to fit together and extremely high friction results between them. The friction is so great that even large amounts of torque cannot separate . . .

Interference fits, commonly referred to as press fits and shrink fits, are traditional methods for joining cylindrical parts.

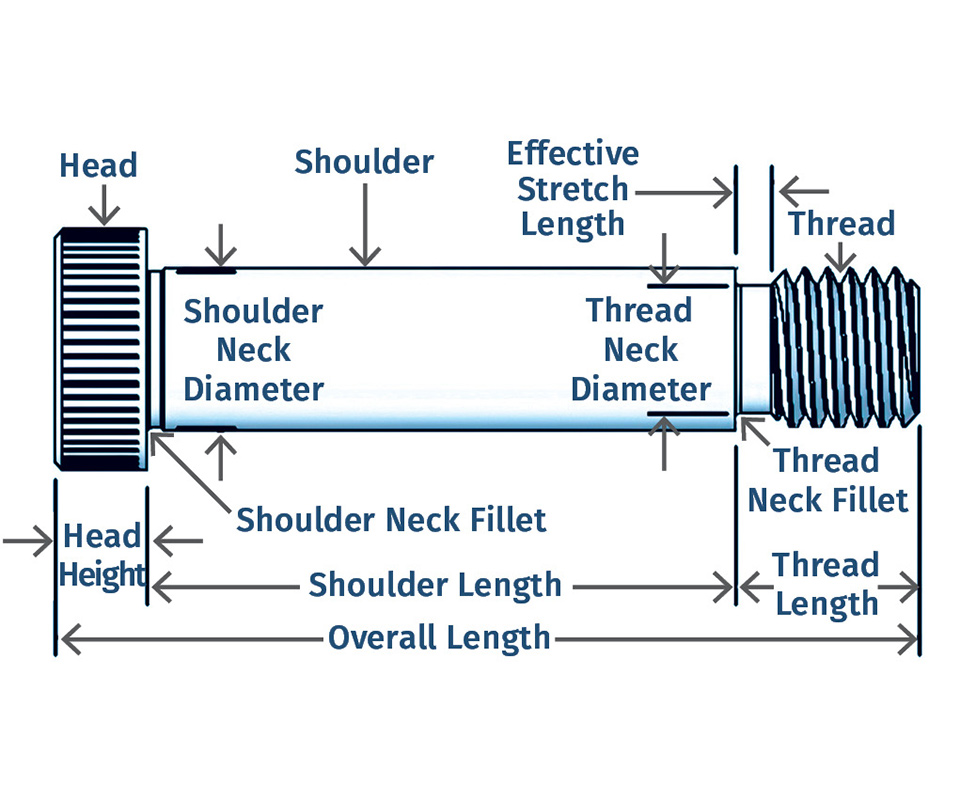

Why Shoulder Bolts Are Too Important to Ignore (Part 1)

Prediction of stress distribution in press-fit process of

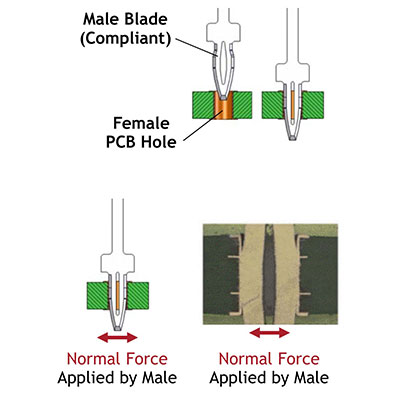

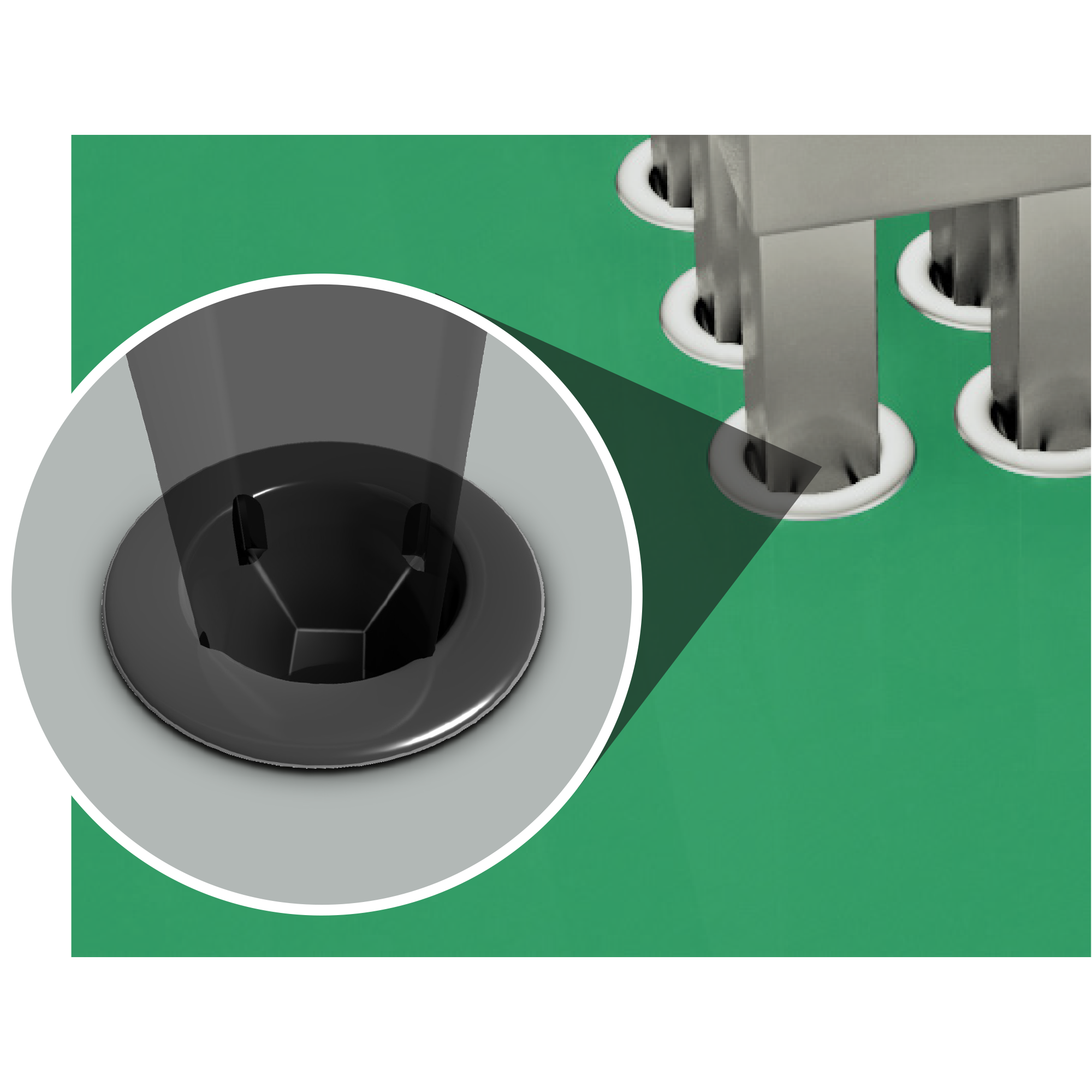

The Principle of Lee Plug Performance

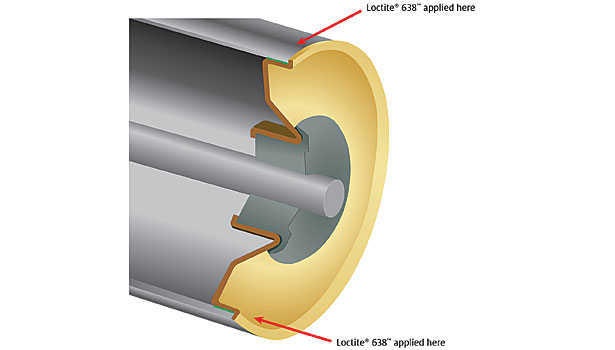

How to Secure Fasteners and Strengthen Interference Fits

Increasing Strength and Reliability of Interference Fits

Increasing the Strength and Reliability of Press Fits

The carrying capacity of conical interference-fit joints with

Increasing the Strength and Reliability of Press Fits

Reliability Paradigm Shift From Time to Stress Metrics - No MTBF

Recomendado para você

-

Understanding Press-Fit, Its Advantages And Applications22 dezembro 2024

Understanding Press-Fit, Its Advantages And Applications22 dezembro 2024 -

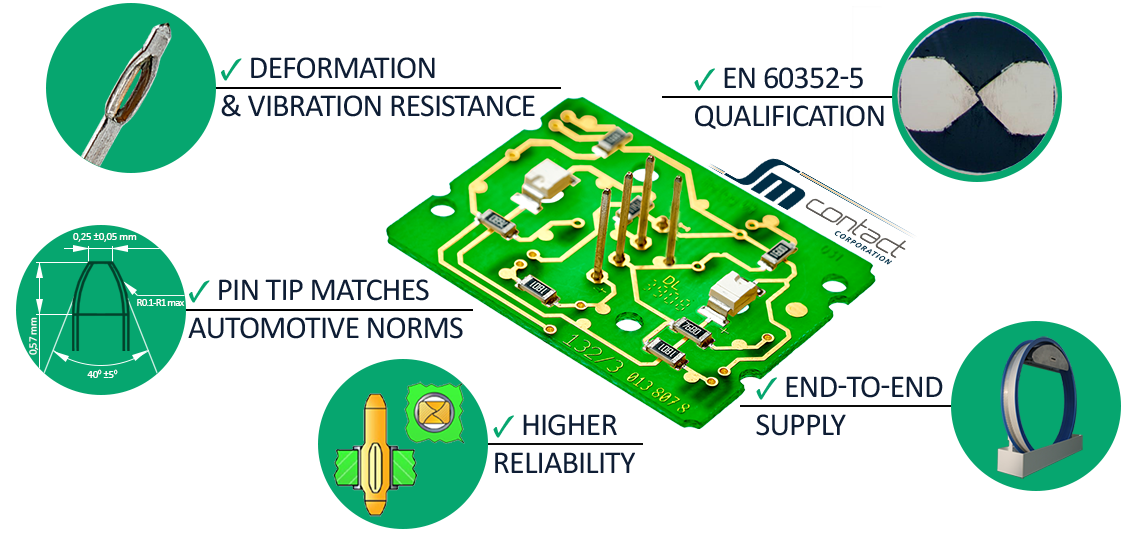

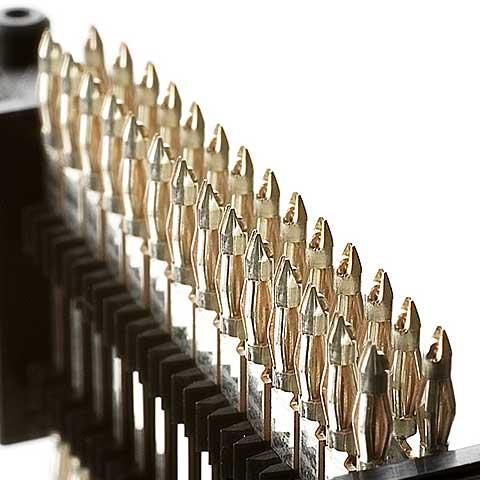

Pressfit technology, press fit equipment, press fit connectors22 dezembro 2024

Pressfit technology, press fit equipment, press fit connectors22 dezembro 2024 -

Press-fit Connectors: Challenges in Circuit Board Assembly22 dezembro 2024

Press-fit Connectors: Challenges in Circuit Board Assembly22 dezembro 2024 -

ISFIT® (Press-Fit Terminal)22 dezembro 2024

ISFIT® (Press-Fit Terminal)22 dezembro 2024 -

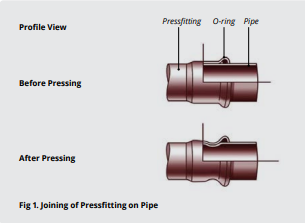

Press-fit VS welded piping: Which should I choose?22 dezembro 2024

Press-fit VS welded piping: Which should I choose?22 dezembro 2024 -

How to remove press-fit bottom bracket bearings in 12 easy steps22 dezembro 2024

How to remove press-fit bottom bracket bearings in 12 easy steps22 dezembro 2024 -

Press Fit Instructions (English)22 dezembro 2024

-

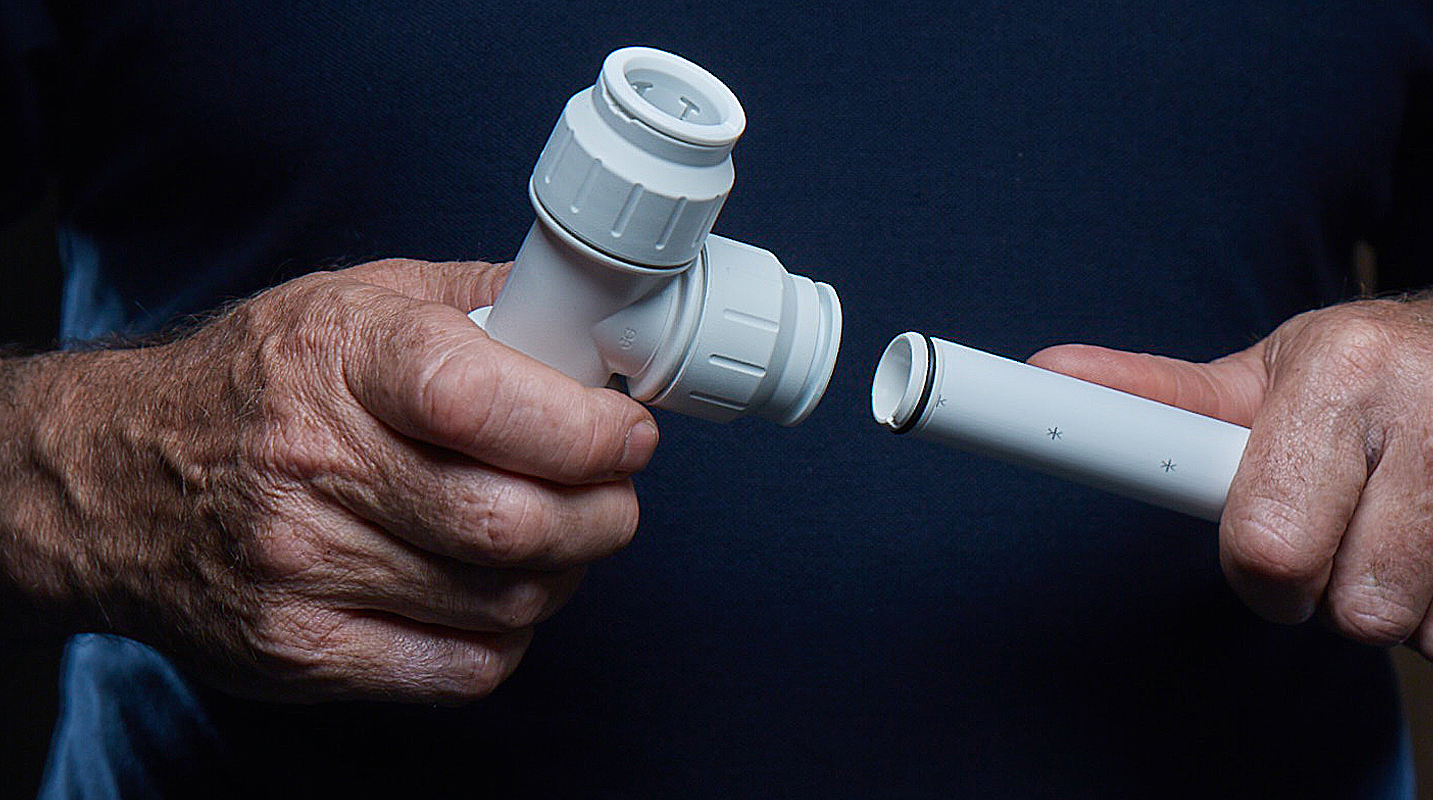

JG Speedfit push-fit plumbing and heating22 dezembro 2024

JG Speedfit push-fit plumbing and heating22 dezembro 2024 -

Press Fit Technology Explained22 dezembro 2024

Press Fit Technology Explained22 dezembro 2024 -

WP-BUTR REDCUBE PRESS-FIT with internal thread, two-rows, Electromechanical Components22 dezembro 2024

WP-BUTR REDCUBE PRESS-FIT with internal thread, two-rows, Electromechanical Components22 dezembro 2024

você pode gostar

-

Epic Wubbox, My Singing Monsters Wiki, Fandom in 202322 dezembro 2024

Epic Wubbox, My Singing Monsters Wiki, Fandom in 202322 dezembro 2024 -

Chai: IJM Rimbayu offers Avela phase 17C buyers the chance to win22 dezembro 2024

Chai: IJM Rimbayu offers Avela phase 17C buyers the chance to win22 dezembro 2024 -

Vestido Infantil Barbie Filme Xadrez Festa Luxuoso - Charlotte22 dezembro 2024

Vestido Infantil Barbie Filme Xadrez Festa Luxuoso - Charlotte22 dezembro 2024 -

Withered Foxy Jumpscare frame by XSlayerXP on DeviantArt22 dezembro 2024

Withered Foxy Jumpscare frame by XSlayerXP on DeviantArt22 dezembro 2024 -

Residencial Venturi22 dezembro 2024

-

Espanha x Inglaterra na final da Copa do Mundo Feminina: onde assistir, data e horário - Lance!22 dezembro 2024

Espanha x Inglaterra na final da Copa do Mundo Feminina: onde assistir, data e horário - Lance!22 dezembro 2024 -

![Ahri KDA [ALL OUT] - League of Legends [4K Version] (Wallpaper Engine) on Make a GIF](https://i.makeagif.com/media/3-16-2021/v77-9b.gif) Ahri KDA [ALL OUT] - League of Legends [4K Version] (Wallpaper Engine) on Make a GIF22 dezembro 2024

Ahri KDA [ALL OUT] - League of Legends [4K Version] (Wallpaper Engine) on Make a GIF22 dezembro 2024 -

Stephanie Panisello On Recreating Resident Evil's Claire For Modern Audiences22 dezembro 2024

Stephanie Panisello On Recreating Resident Evil's Claire For Modern Audiences22 dezembro 2024 -

ArtStation - Pokemon Scarlet - Koraidon22 dezembro 2024

ArtStation - Pokemon Scarlet - Koraidon22 dezembro 2024 -

Uzaki chan wa Asobitai! DUBLADO CENA EcosEstúdios22 dezembro 2024

Uzaki chan wa Asobitai! DUBLADO CENA EcosEstúdios22 dezembro 2024